The Ersatz Chronicles – From Scrap to Strap: Recycled Rubberized Cloth in German WWII Equipment

By late 1943 and early 1944, the German war industry had largely abandoned the use of premium materials in favor of recycled and ersatz substitutes. Damaged, outdated, or captured enemy gear was systematically stripped for reusable components, allowing for the continued production of essential field equipment. This process not only highlighted the adaptability of German manufacturing but also underscored the extreme resource scarcity faced in the final years of the war. In this series of posts called ‘The Ersatz Chronicles’ we will focus on different kinds of optimalisation of the German war industry with a ever dwindling amount of raw material and the rise of demand.

The utilization of obsolete uniforms and equipment in late-war production remains a key aspect of German military history, reflecting both ingenuity and desperation in the face of mounting logistical challenges.

In this post we will focus on the rubberized woven ‘Ersatz’ substitute for webbing straps used on German weapons related equipment between 1943 and 1945.

The material exhibits a woven or braided structure, indicating a deliberate reinforcement method for durability. The presence of mixed-colored material suggests a textile-based reinforcement, possibly made from cotton or linen. This fabric was coated on one side with a thin rubber layer. This is a indication that the material was most probably sourced from rain or chemical i.e. gas repelling material. There is a theory that this material was sourced from downed barrage balloons. This theory is not logical for me for multiple reasons I will explain below the photo.

The material is razor thin and only coated on one side of the material. The gas retaining properties for barrage balloons would need thick, double coated material. Additionally the mere immense size of these balloons themselves and the thin material would not suffice in these large mid air floating contraptions. Another indication for it being sourced from a different raw material is the size. Not the length of the strap as is; but looking closely at the weave it tells us that it the vertically woven pieces are constructed from small scraps, mostly not larger then 30 cm’s in length. With these large balloons; one would expect that longer scraps would greatly aid in the production process and speed. Looking at the strap material below we can see that the light grey colour only appears for a short part. Counting the vertical rows from left to right in the light grey material we can roughly cound 16 passes. This strap above is attatched to a MG42 barrel carrier and is 2,5 cm in width indicating between 30 and 40 cm in length on average. This is ofcourse a rough estimate but it shows the short lengths of material utilised.

A closeup of a raw end of the material showing that the base of the material is the same type of material but folded in long lengths in the full horizontal length of the strap. The longer scraps were thus reserved for the lenght of the strap, not the width. In this full length of the strap it can be seen that sometimes it is made from one piece and sometimes made from several scraps tightly knit together. One can also see the coarse hand sewing of the material fixing it. Another way of fixing the end of a strap would be sewing over a piece of rubberized cotton.

Below we can see two types of this woven material; the upper being made out of less thick, more loosely woven material with less rubber content. There are also some variants of this material without any rubber at all showing on the outside. Whilst it could still just be the process of manufacturing whereas the material used as reinforcement is simply folded up or rolled. With the latter being possible to externally show just the rubberized, or inside of the material.

Now I hear you thinking; if it is not made from barrage balloons; what is the source of the raw material? My guess is that these straps were made from damaged sets for the Wehrmacht issue Leichte Gasbekleidung 39 or lightweight gas protective suit. The reason for this guess is the fact that it is by 1943 it was mostly obsolete. It was a standard issued piece in 1939 yet it was mostly seen unused by 1943.

The bag for the Gasbekleidung 39

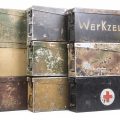

Here we see the Ersatz woven material photographed on top of several Gasbekleiding 39 pouches. The colours are typically the same, a wide range of grey, green and broen canvas coated on one side, exactly the material as we can see on these straps.

This is one of the shoes, rolled up fully, unissued as is. The shoes itself have a rubber sole and long rubberised calfs. When fully unfolded the calves are roughly between 50 and 70 cm long, long enough to make parts of the horizontal base lines for the vertical weave.

It is logical for me, that possibly damaged gas suits were repurposed into raw materials. These gas protection suits are fragile and if worn could easily be damaged. Having a damaged and thus leaking suit that is supposed to protect you from biological and chemical substances is useless and therefor should be repaired or replaced. Given the rubberized nature of these suits it could easily be concluded that having a damaged suit would render the suit useless, repairing a rubberized cloth is a heinous job and with considerable wear would present the need for the resealing of the whole garment in stead of one small damage. Also it would need for every single set to be meticulously checked for small cuts and damages. This with a 5 part clothing set which is made of sticky rubber, easily damaged and with many folds, creases and edges to check would prove costly in time and thus cost when need to be checked in the thousands. Without having exact production numbers at hand; it is plausible that there would have been thousands if not hundred thousands sets made and most of them, unissued. This, by 1944, would present the German army with a highly probable large stock of otherwise hardly used rubberized cloth in the form of gas suits. And thus a great opportunity for recycling. Whilst I can not prove this theory; I would love to see other rubberized Wehrmacht issued cloth or uniforms which is only coated on one side besides the obvious gascape pouches.

I have not seen any conclusive evidence pointing towards barrage balloons being recycled for these purposes besides it being the most popular theory for the source of this raw material. Neither do I have access to, or high resolution images that can support this theory with close ups of the material. I also believe that merely gas proofing for personal protection and to make a large balloon gas tight two completely different thing which would prove more to the point of the material utilised for these straps not being of these balloons which probably, were used and repaired constantly. These barrage balloons would probably be made of more thick material to start with. Which in my opinion is too thick.

The woven straps were used for ammunition related equipment only. I have seen a large number of these items which saw much use on the western front, namely as early as the Normandy invasion. There are a number of items I have observed in this material I will list below. There is one exception, which I sadly do not own and have only seen only one time, 18 years ago. This was a set of pouches for the rifle grenades. If someone that owns it today wants to share some photos I would be very interested to see it again. There might be other utilisations of this material but I have not found it.

The Tragegestell 43 was first produced with tightly woven webbing straps with integral holes for the buckles adjusting the carrying straps. These carrying frames were made to carry three MG34 u. MG42 ammunition cases. These features are also seen on the late war variants manufactured with woven rubber straps yet only the adjustable parts have these details. Interestingly these items were made alongside eachother with both frames shown above dated 1945.

The left one is marked bvk1945 indicating production by Schöne, Joh., Gottfried, Großröhrsdorf i/Sa.

The right one is marked htp 1945 indicating production by Daber & Co.,E., Heeresbedarf, Berlin SW68

Arguably the Tragegurt 34 is the best known example of the woven material. They are manufactured exactly like the earlier webbing counterpart with the difference of the ommitting of one of the two sliding webbing loops and the belt hook sticking trough the weave in stead of having a embroidered eyelet. Although the basic model is adjustable in length there is a second model which lacks the the buckle and adjustable functionality. This is only seen with the Ersatz type of strap so it probably has someting to do with the stiffness of the material not passing trought the buckle easily or sometimes too easy when the strap is woven too thin.

As one can see the simplification of the strap. The hooks itself being lightly blued metal without painted finish. These straps show obvious last ditch production in all facets.

Two late war Laufschützer or spare barrel carriers for the MG42. The straps on these carriers was normally made from tightly woven webbing material. There are two models of straps; the first one is adjustable and the second model saw its adjustability with the buckle ommitted.

The strap above was designed to pull the ‘Akia’ sled which was modeled after the Finish army model. These straps are like the artillery and cart pulling straps considerably wider then the Tragegurt or Laufschutzer straps. The wooden toggle wound be attatched to the sled and the strap slung diagonally across the body. This strap is visually made from more coarsely woven material, not all of it being rubberized.

The last strap on this list is the typical strap for pulling infantry carts, horse drawn wagons, artillery pieces and more. These straps also exist in two versions; one with and one without a size adjusting buckle.