The Coconut canteen; Ritters not so tropical canteen

Frederik Suijkerbuijk, 25 July 2022

Introduction

The so called coconut canteen or Kokosnuss can be observed with markings as early as 1941 indicating its first year of production. These canteens are often referred to as being tropical issue because of their webbing straps as used for other tropical issue equipment. The truth is that even though they first came out around the time the Afrikakorps ventured to Italian held Libya; these were probably not intended for sole tropical use. These canteens have mostly been mislabeled being tropical; therefore I try to explain the matter and the mystery about the Coconut canteen. Having collected and inspected numerous examples it is clear that most if not all canteens are slightly different. These are very collectible in their own right and caution should be taken; collecting these can be very addicting.

The material

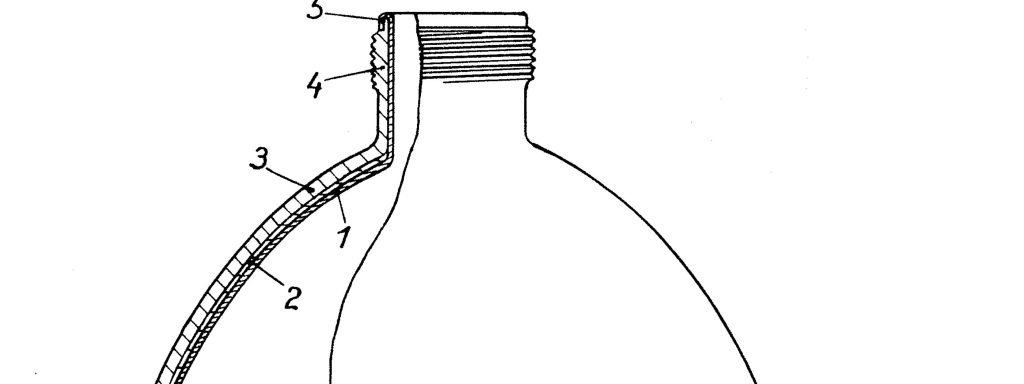

The base of the canteen is a standard Model 1931 flask, encapsulated in a layer of wood paste covered with pressed wood slices or veneer and resin. This so to say ‘cover’ was meant as a insulator and to offer more resistance to wear then the its standard felt counterpart. The wood veneer is cheap to produce, strong and lasts for a long time; ground dug examples are often in good shape whereas items found around it have long perished. The coconut is not made out of bakelite which is, like wood veneer, a variant on resin; but with a totally different chemical composition.

2. The wood pulp paste applied prior to laminating

3. 3 layers of wood veneer

4. The bottle neck thread

5. The top of the neck and its rounded off aluminum layer.

The manufacturer

The coconut canteen was patented by the firm of Heinrich Ritter from Esslingen am Neckar, who had a large firm called Ritter Aluminium producing kitchenware. It was originally founded in 1911 and was one of the first factories to work with the then new material Aluminum. In the 1930’s they specialized in ships kitchenware but soon expanded to military equipment. It was one of the major producers for canteens and messkits for the German army.

Ritter produced many canteens and mess kits during the war. They made the M31 canteen between 1935 and 1943 after which they fully switched to the coconut canteens. They never made the M42 canteen in steel yet they did make steel cups for the coconut. They made the M31 mess kit from 1935 and 1945 without pause.

Interesting fact that I just found out is that Heinrich Ritter was merely the patent holder and did the final assembly of the flasks. The production or covering of the flasks themselves was done by Dübelwerke Berlin. Below you will find the direct translation about the documents below.

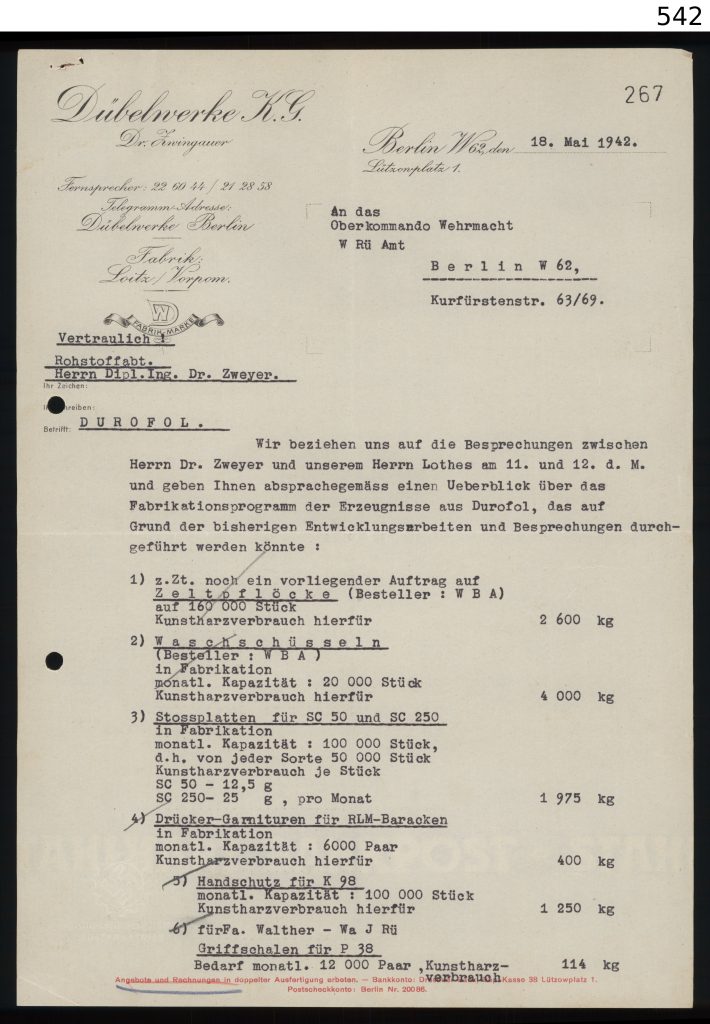

-1-

Dübelwerke K.G.

Dr. Zwingauer

Berlin W 62, 18 May 1942

Lützowplatz 1

To the

High Command of the Wehrmacht

Weapons & Equipment Office

Berlin W 62,

Kurfürstenstr. 63/69

Confidential

Raw Materials Department

To Mr. Dipl.-Ing. Dr. Zweyer

Subject: DUROFOL

We refer to the discussions between

Dr. Zweyer and our Mr. Lothes on the 11th and 12th of this month

and, as agreed, provide you with an overview of the

production program of articles made from Durofol,

which could be carried out based on previous development work

and discussions:

- Currently an existing order for

tent blocks (Customer: WBA)

for 160,000 pieces

Resin consumption for this — 2,600 kg - Wash basins

(Customer: WBA)

In production

Monthly capacity: 20,000 pieces

Resin consumption — 4,000 kg - Shock plates for SC 50 and SC 250 bombs

In production

Monthly capacity: 100,000 pieces,

i.e., 50,000 pieces of each type

Resin consumption per piece:

SC 50 — 12.5 g

SC 250 — 25 g

Monthly total — 1,975 kg - Handle sets for RLM barracks

In production

Monthly capacity: 6,000 pairs

Resin consumption — 400 kg - Handguard for K 98

Monthly capacity: 100,000 pieces

Resin consumption — 1,250 kg - For firm Walther – Wa J Rü

Grip panels for P 38

Monthly requirement: 12,000 pairs

Resin consumption — 114 kg

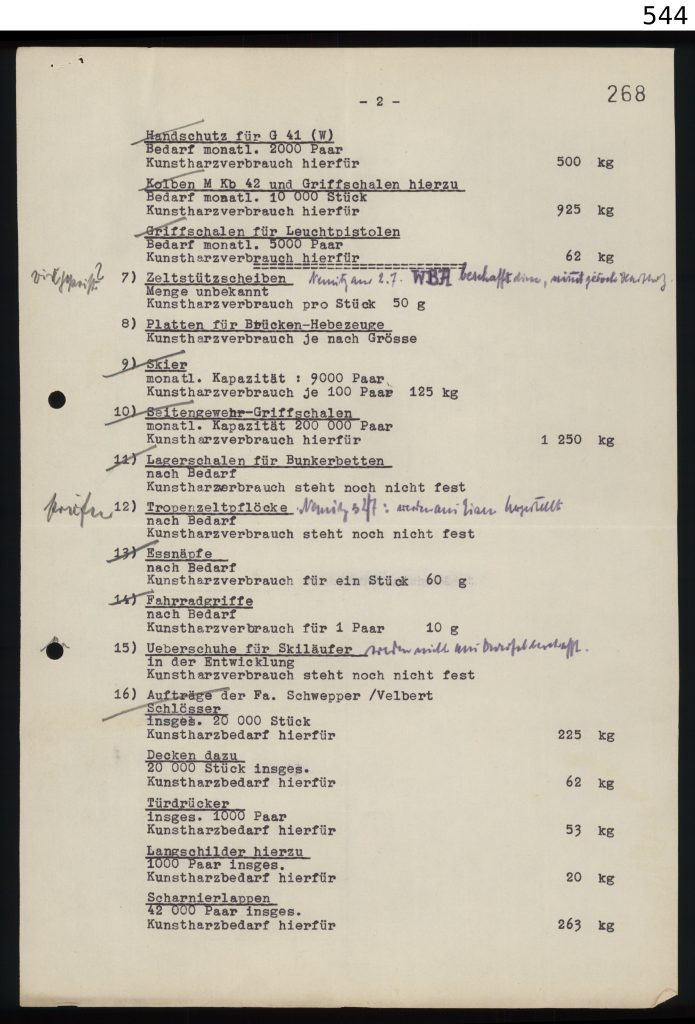

-2-

Handguard for G 41 (W)

Monthly requirement: 2,000 pairs

Resin consumption — 500 kg

Stocks for M Kb 42 and grip panels for them

Monthly requirement: 10,000 pieces

Resin consumption — 925 kg

Grip panels for flare pistols

Monthly requirement: 5,000 pairs

Resin consumption — 62 kg

- Tent support discs

Quantity unknown

Resin consumption per piece — 50 g - Plates for bridge-lifting equipment

Resin consumption depending on size - Skis

Monthly capacity: 9,000 pairs

Resin consumption per 100 pairs — 125 kg - Bayonet grip panels

Monthly capacity: 200,000 pairs

Resin consumption — 1,250 kg - Bearing shells for bunker beds

As required

Resin consumption not yet determined - Tropical tent blocks

As required

Resin consumption not yet determined - Mess bowls

As required

Resin consumption per piece — 60 g - Bicycle grips

As required

Resin consumption per pair — 10 g - Overshoes for skiers

In development

Resin consumption not yet determined - Orders from firm Schwepper / Velbert

Locks

Total: 20,000 pieces

Resin requirement — 225 kg

Covers for them

20,000 pieces total

Resin requirement — 62 kg

Door handles

Total: 1,000 pairs

Resin requirement — 53 kg

Long plates for them

1,000 pairs total

Resin requirement — 20 kg

Hinge flaps

42,000 pairs total

Resin requirement — 263 kg

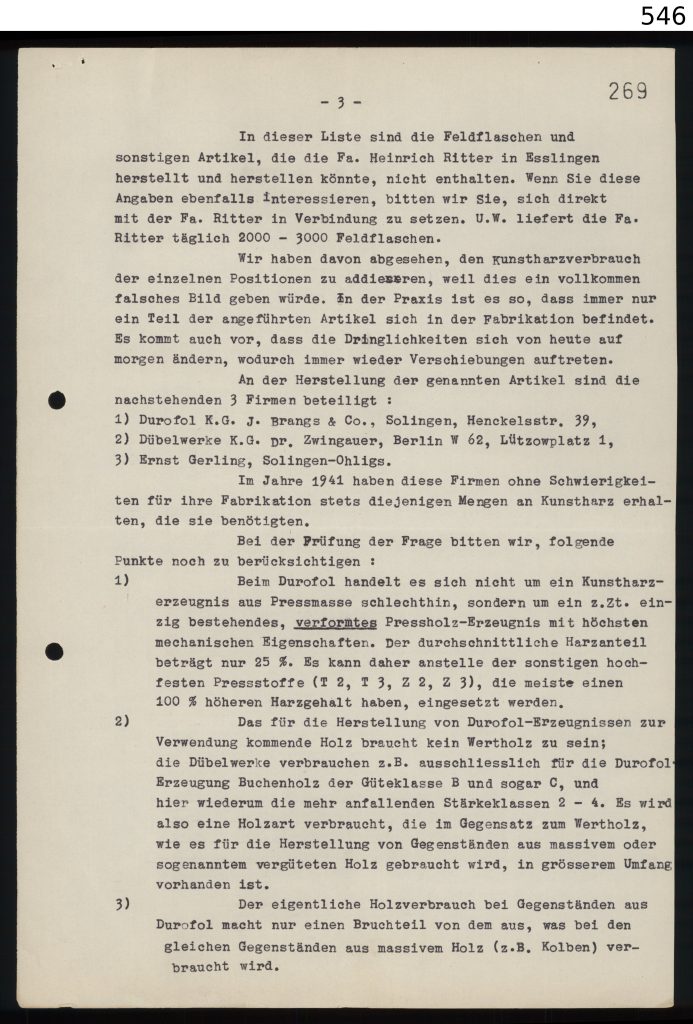

– 3 –

This list does not contain the canteens and

other items produced or potentially producible by Heinrich Ritter

Company in Esslingen. If you are also interested in this

information, we ask you to contact the Ritter Company directly.

Our works deliver 2,000–3,000 flasks to the Ritter Company daily.

We have refrained from adding up the resin consump-

tion of the individual items because this would give a completely

false picture. In practice, only part of the listed items is

being manufactured at any given time. It also occurs that

urgencies change from one day to the next, causing continuous

shifts.

The following three companies are involved in the

production of the mentioned items:

- Durofol K.G. J. Brangs & Co., Solingen, Henckelsstr. 39,

- Dübelwerke K.G. Dr. Zwingauer, Berlin W 62, Lützowplatz 1,

- Ernst Gerling, Solingen-Ohligs.

In 1941, these companies received without difficulty

the required quantities of resin for their production.

When considering the matter, please take the following

points into account:

- Durofol is not merely a resin-molding compound, but the

only existing formed pressed-wood material with exceptional

mechanical properties. Its average resin content is only 25%.

Therefore it can replace other high-strength molded materials

(T 2, T 3, Z 2, Z 3), which usually have twice the resin content. - The wood used for the production of Durofol items does

not need to be quality wood; for example, Dübelwerke use only

beech wood grade B and even C, particularly the surplus

strength classes 2–4. Thus, a type of wood is consumed which,

unlike high-quality wood required for solid or laminated items,

is available in larger quantities. - The actual wood consumption for Durofol items is only a

fraction of that required for identical items made of solid

wood (e.g., stocks).

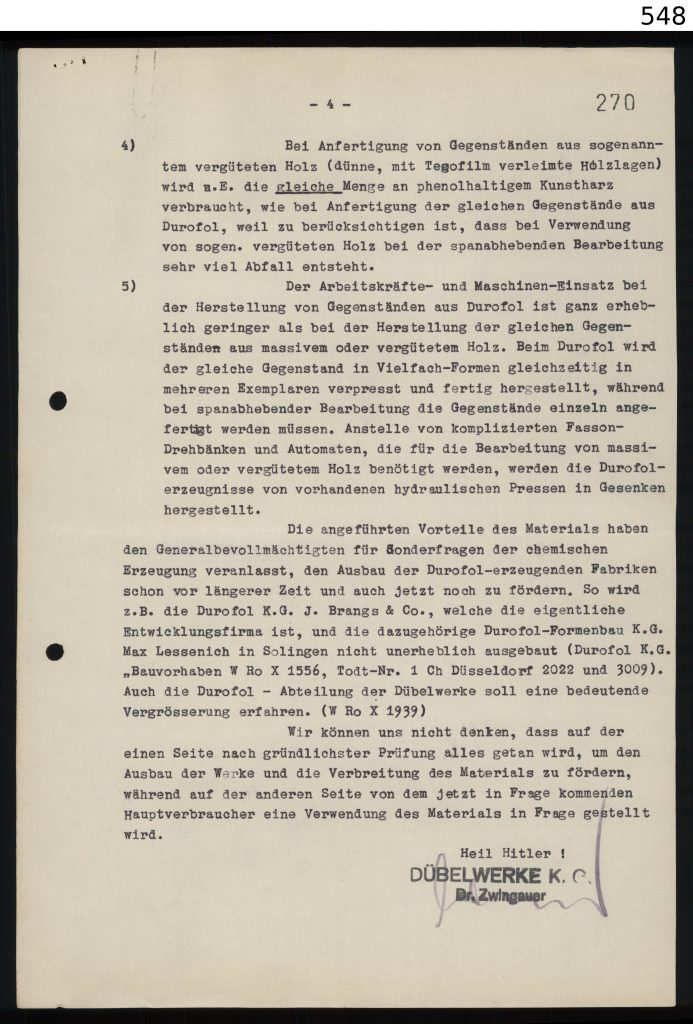

– 4 –

- When manufacturing items from so-called laminated

treated wood (thin layers glued with Tegofilm), in my opinion the

same amount of phenolic resin is consumed as in the manufacture of

the same items from Durofol, because it must be considered that

laminated wood produces a great deal of waste during cutting

operations. - The labor and machinery required for producing

items from Durofol is significantly lower than for identical

items made from solid or laminated wood. With Durofol the same

item is pressed and finished in multiple cavities of one mold

simultaneously, while with cutting processes each item must be

worked individually. Instead of complicated profile lathes and

automatons required for solid or treated wood, Durofol products

are made using existing hydraulic presses and die molds.

The advantages listed above have prompted the

General Plenipotentiary for Special Questions of Chemical

Production to expand the Durofol-producing factories already some

time ago and still now. For example, Durofol K.G. J. Brangs & Co.,

which is the primary development company, and its associated

tooling company Max Lessenich in Solingen are being substantially

expanded (“Construction project W Ro X 1556, Todt-No. 1 Ch

Düsseldorf 2022 and 3009”). The Durofol department of the

Dübelwerke is also intended to undergo a significant expansion

(W Ro X 1939).

We cannot imagine that on the one hand, after most

thorough examination, everything is being done to expand the plants

and promote the spread of the material, while on the other hand the

main consumer now under consideration should reject the use of

this material.

Heil Hitler!

DÜBELWERKE K.G.

Dr. Zwingauer

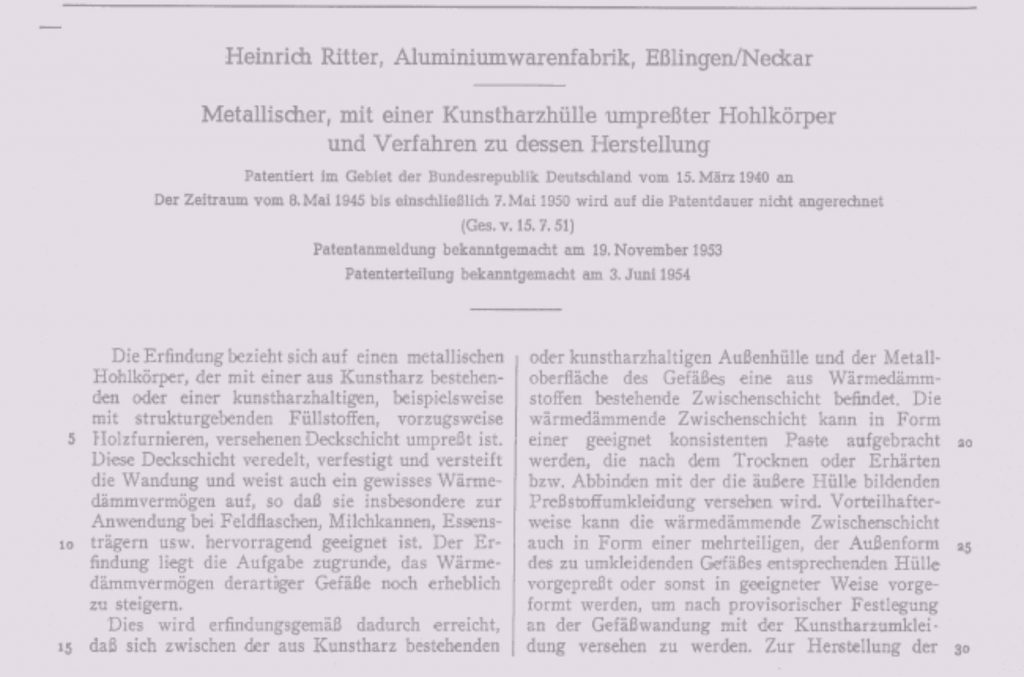

The Patent

Heinrich Ritter, Aluminiumwarenfabrik, Esslingen/Neckar applied for the patent 15th of March 1940. The patent remained the ownership until 1953 when it was applied for again and acknowledged in 1954. The patent describes a metallic bottle which is encapsulated within a artificial resin or Pressstoff with wood veneer. These layers strengthens and insulates with warmth retaining properties for the contents. This patent refers to use with canteens, milk canisters and food carriers. So far we only see the use with canteens. The invention has the task of retaining heat rather then cooling.

The sub producers

Years of production

Although the patent was registered the 15th of March 1940, the coconut canteen was officially produced and issued between 1941 and 1945. The flasks themselves can be found dated 1941, 1942, 1943 and 1945. There is no example dated 1944 although we can see components which are dated to that year. There are hooks and friction buckles dated 1944 mostly come on 1943 and 1945 dated flasks. This is a indication that either in 1944 production was halted; or that they simply used 1943’s press molds. I have not seen any solid proof proving that production either continued in 1944 nor that it was halted. We just know there are no 1944 dated flasks known in collections as of now.

Untouched 1943 dated coconuts can be often found with HRE45 marked cups. This indicates that the line of production probably stopped in 1943 and was picked up again in 1945.

Interesting enough; we can find cups, hooks and friction buckles dated 1944; but no flasks. There are several theories that all are plausible yet we don’t have any proof for either.

– The factory overproduced in 1943, finishing their product as late as 1945

– The factory was bombed out in 1943

– The army didn’t like the canteen or it was too expensive to produce and later reinstated it again because of equipment shortages.

Flask markings

The flask itself is marked on the convex side with the following codes;

D.R.G.M. – The patent Deutsches Reichsgebrauchsmuster, meaning its design and use was registered and protected. This is not a patent although the Germans often referred to this being the ‘Kleines Reichspatent’.

H.R.E. 41 – the producer Heinrich Ritter, Esslingen 1941

D.R.P. angm. – Deutsches Reichspatent Angemeldet; meaning it was applied for the German Reichspatent office protecting its design and use.

Letter or number; this is a code for the mold of the product also seen on phenolic resin or bakelite items. This code could identify from the finished product when a mold needed maintenance or replacement. In short terms; when a batch of coconuts was inspected they would look for damages in the wood that occurred during production. With the mold markings; one could instantly see which mold needed fixing or replacement. This is a feature on most if not all bakelite or molded Pressstoff items.

The Afrikakorps connection

The coconut canteen is said to been designed specifically for the Afrikakorps; but is its design logical, let alone usable in a tropical climate? When we look at the canteen it is obvious that the pressed veneer covering the flask has a very dark colour; making it not the ideal colour to keep out heat in the sun let alone in tropical climates such as north africa. The thick wood veneer is otherwise a great insulator retaining the temperature inside as well as the felt cover does. A well known period newsreel showing Afrikakorps Panzer men cooking eggs on a mere black surface on their Panzer II without a heater is a clear indicator that having dark colours in a climate like that is definitely not a good idea.

I tested two canteens; one ‘tropical’ 1 Liter Labeflasche with felt cover and a Coconut canteen. Both filled with water and casually placed in a sunny environment with 38 degrees Celsius. After one hour the results were interesting; the ‘tropical’ Labeflasche was exactly the air temperature of 38,9 degrees Celius with the contents warm but drinkable. The coconut canteen on the other hand was 49,9 degrees Celsius with its content too hot to consume. My choice in the tropical heat? Quite obvious.

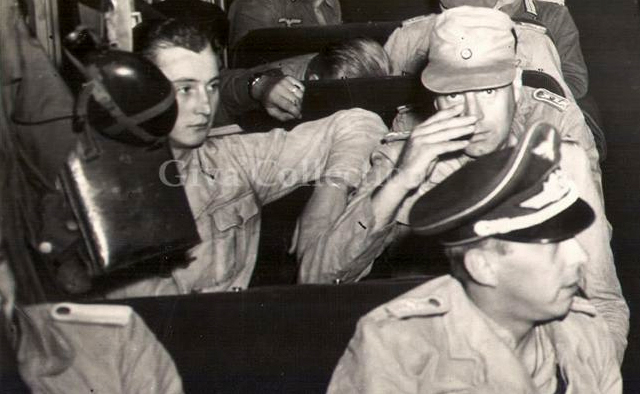

Having looked at tons of images we can not find a single image of a coconut canteen in use with the Afrikakorps. The closest shot we get is a set of prisoners of war riding a train in the United States showing a first pattern coconut with square tips. In my opinion; if it did make it to Africa, it was probably in small numbers in its initial field trials and most probably in its earliest shape with square metal tips which can be observed in the photo below.

The connection to the tropical equipment is the assumption that all equipment manufactured with webbing instead of leather is instantly a tropical issue item but there are many equipment items with webbing or canvas which are not specifically tropical. Allthough we can not prove it was not a specifically tropical item can not disprove it either; it just makes no sense filing in a patent for something that was irrelevant early 1940.

Two main models

There are two main variants that one can identify. The earliest examples carried a unmarked square metal tip The variation is mainly in the closing strap. One being a Ritter patent friction buckle, the other being a simplified roller-buckle. I have seen the roller buckles on canteens as early as 1942, but never before. The specific friction buckle is also made and patented by Ritter and can be seen on the earliest coconut canteens.

I choose to remain with these two main variants to keep things clear. The cup, the material of the straps and hardware varies too much whilst there are just two types of closure buckles. I will deal with small variating differences later in this article.

Variations

There are many, maybe uncountable variations that make collecting interesting. These variations are mostly attributed to fabrics and cups which are so diverse that there is always a new variant to discover that is different in a way. Most of these variations are subtle and small; hardly noticeable for the novice collector. A lot of the variations can be seen in the material utilized for the straps. The tan webbing turned into a mix of several colors and later several materials around 1943.

Type 1 friction buckle

Although countless variants exist here are 6 different variants of main strap material. All are different and my assumption is that the Ritter factory worked with subcontractors and or used whatever was available to construct the straps. On these photos you can also see the pencil markings for the sewing indicating the placing of certain elements.

The Harness in details

Securing the strap to the breadbag or securing the cup to the flask meant a piece of webbing was looped trough a buckle and pushed through a retaining loop. Without some sort of modification this would mean a short lifespan to the webbing which would easily fray and require repairs. The Germans used a wide variety of metal or leather points to stop fraying of webbing equipment. Generally, there are two types as used on the Coconut canteen and we can identify at least two different manufacturers. We can find unmarked examples or marked LUX or SBH. I have not encountered any other maker markings on these canteen points having studied 100 canteens.

This simple folded metal clip is only seen on 1941 and 1942 dated coconut canteens. It is a simple but effective point to stop the fraying of the webbing. Considering we see this only on the early canteens we can assume this is a early production by the Ritter factory prior utilizing SHB or LUX tips en masse and shifting to the well known triangular shaped metal tip.

The SBH and Lux marked tips look alike; but they are not the same. The SHB marked tips are made from a single sheet of metal whilst the LUX marked examples are made out of two separate pieces. In this way; we can identify the maker of the unmarked example shown above. The most common metal tip to find is marked SHB, the LUX marked examples are less common. I have found painted and galvanized examples. I have not found any other markings on the metal tips having studied 100 coconut canteens.

In general there were 4 types of caps as used on the coconut canteen with one example specifically made for the coconut canteen; it is not encountered on any other canteen and it is made from the same material as the canteens itself. Please note; the brown leather strap on the first canteen cap shown is a replacement.

From left to right;

1. Aluminum Modell 1931 canteen cap marked HRE43

2. Second pattern black resin canteen cap as used post 1942.

3. Specific canteen cap for the Coconut canteen

4. First pattern black resin canteen cap

The harness is secured onto the flask by means of a leather strap around the neck. This leather strap is made out of pigskin leather and is secured with a black painted roller buckle. The straps can be marked and dated HRE, JSD, WIKO or REP. It is sewn on the inside of the canteen and looped through a piece of harness at the outside of the canteen.

The clasp sewn onto the canteen harness can be mounted in several ways. The clasps are not always marked but most are marked Patent Ritter and or HRE inside the clasp. These clasps are galvanized or painted in grey, green, blue or red.

Cups for the Coconut canteen

There are generally four types of cups to encounter on these canteens as fitted from the factory. These are all typical for this type of canteen and as far as I am aware I don’t know of other types issued with the coconut. There of course always exceptions but I choose to focus on the cups that were issued with the coconut from the factory only.

1. Sharp edged aluminum drinking cup, painted or unpainted.

These were made specifically for the coconut canteen. The model was first produced pre war for the 1 Liter medical canteen or Labeflasche. These early examples have a rolled edge. The examples seen on the coconut are less well finished with a sharp raw edge. These can be found in Olive paint or with no paint at all. These can be found unmarked or marked HRE with a manufacturing date. These cups are made right up to 1945. Although there are other manufacturers producing the caps post 1940, the HRE marked examples above, and unmarked examples are typical for the coconut canteen.

2. Modell 31 Aluminum drinking cup with handles.

A typical Aluminum Modell 31 drinking cup in Olive paint. These can be found with steel and aluminum handles.

3. Modell 42 Steel drinking cup with handles

The steel M42 canteen cups can be easily recognized to the shape of the dent in the side of the attachment hinge which is typical for cups made by Ritter and can not be observed at other canteen makers. Compare these to another canteen cup and you will see the different shape on the left hand side of the handle attachment plate. These cups can be seen in olive, brown and red paint. Typically these cups were primed in red oxide and oversprayed externally with olive paint. But there are numerous variations in paint schemes.

– Red inside, green outside

– Green inside and outside

– Red inside and outside

– all of the above can be seen marked or unmarked

4. Phenolic resin drinking cup

These cups are often referred to as being bakelite like the coconut canteen itself; the material used for these cups is a phenolic resins with a variety of fillers creating their unique appearance . There are many colour varieties to be found yet the most common and in my opinion factory fitted examples are always black or brown on the coconut canteens. Unlike other parts of the canteen, I have not found any proof that these cups were made by Ritter so in my opinion they were made by a external manufacturer.

Postwar examples

The coconut canteen was reintroduced post war in the 1950’s and retained the same design at first. The post war models can easily be recognized by the Alfurit markings on the flask or the absence of markings on the cup. There are also postwar canteens marked HRE with postwar dates such as ; HRE 57. The early postwar harnesses are exactly the same as their wartime counterparts with sometimes the same mis match construction which indicates they still had a bunch of wartime parts or harnesses themselves in stock. At some point the harness construction switched to black and brown leather and later in green leather. The post war canteens are also marked DRP. A. because the patent was introduced in the third reich era. These patents were last given out in 1949 and can be seen up until 1952 because the German patents protected for 3 years! Canteens marked Ritter Alfurit D.R.P.a. are presumed to be postwar.

Conclusion

The coconut canteen produced by Heinrich Ritter Aluminiumwarenfabrik was not produced specifically for the Afrikakorps as believed. It was invented pre World War Two as a heat insulating layer. It most probably did better in the eastern cold then it did in the heat of Africa. Although there are little to none proofs that the coconut canteen made it to Africa and if so, in small numbers. On the other hand; there are many coconuts to be observed photographed on the eastern front. This indicates that it was either too late or probably not well suited for the hot climate. The truth is that there is no connection with these canteens and tropical equipment. Their design makes them look like a coconut, but that’s the same comparison as that the Tornister or ‘Affe‘ should be made for monkeys.

Thanks to; Otto, Luuk, Andreas, Dirk, Chris and Olaf