The Bakelite 6×30 CXN Dienstglas by Emil Busch

A small selection of binoculars, parts and cases used for this article

When I first started collecting German militaria I had a few things I really wanted to find. One of them was the elusive Bakelite 6×30 Dienstglas manufactured by Emil Busch in 1944. Being fascinated by bakelite and artificial leather equipment it had to acquire a set for my collection. The first pair I acquired had a damaged main hinge. The second pair was all good and I still own it today. Of the many questions I had regarding its production and issue I can only answer a few. Looking at it logically I can only suppose it was just another form of raw material saving for the Wehrmacht. But when I dove into the details of these optics there is so much more then just a interesting design. They are beautifully designed and in some way the grandfather of modern plastic army binoculars.

A textbook set with its accompanying case, the Knopflasche is missing on this example

Late in the war the company of Emil Busch, Rathenow produced a set of binoculars in the standardized Heer format with 6×30 magnification. It is known to collectors as the Bakelitglas or bakelite 6×30 Dienstglas binoculars. Some might say that these binoculars are a latewar ‘Ersatz’ last ditch product and therefore bad quality. However these binoculars produce great optical results and feature a number of innovations which are often overlooked by most collectors. Both main lenses feature eccentric steel inserts which simplify the alignment or collimation during the production. Each side uses two different sized prisms which are mounted in a shock resistant set of 4 bakelite resting points and secured with a blued metal band. This was developed with the aim to produce a robust military grade binocular while avoiding the use of scarce raw materials. It was produced with approximately 200 grams of bakelite, 140 grams of optical glass and 200 grams of steel and zinc or zinc alloy. These binoculars all come in cases dated 1944. I have not observed a example dated 1943 or 1945 yet sometimes the closing latches are dated 42 or 43. My guess is that these binoculars were first made in 1944 right until it’s producers went ‘out of business’ when the Americans and Russians occupied their factories.

The lowest known serial for the bakelite 6×30 Dienstglas can be seen above; 364156. Interestingly enough its body shows signs of the second model of production with visible metal studs underneath ánd a larger aperture in the central hinge, a detail that would be void until serial 384478.

It is unknown whether the design was made up by Emil Busch or it was commissioned by the army. Both explanations would be logical. The design for the binoculars features several challenges. Bakelite as a base material for the binoculars is a logical choice in a war torn country with very little raw materials to utilize in the production of optics necessary to fight a war. Before the war binoculars were made utilising expensive raw materials such as brass. Approximately in 1940 they switched to Aluminium and later to Zinc to manufacture the housing of optical instruments. Bakelite was the last resource for manufacturing the housing of 6×30 magnification binoculars for use with the Wehrmacht and Waffen-SS. Although a good substitute, bakelite isn’t a perfect base for binoculars. It is a fragile material which is easily damaged and it does not have good properties for moving i.e. adjustable parts. These moving and adjustable parts would have been made in Zinc or Metal creating a interesting mix of parts. It is known that Emil Busch produced a binocular called ‘Heda’ with bakelite body in the 1930’s for the use in theatre.

A side by side comparison of the issue 6×30 magnification binoculars with its bakelite counterpart

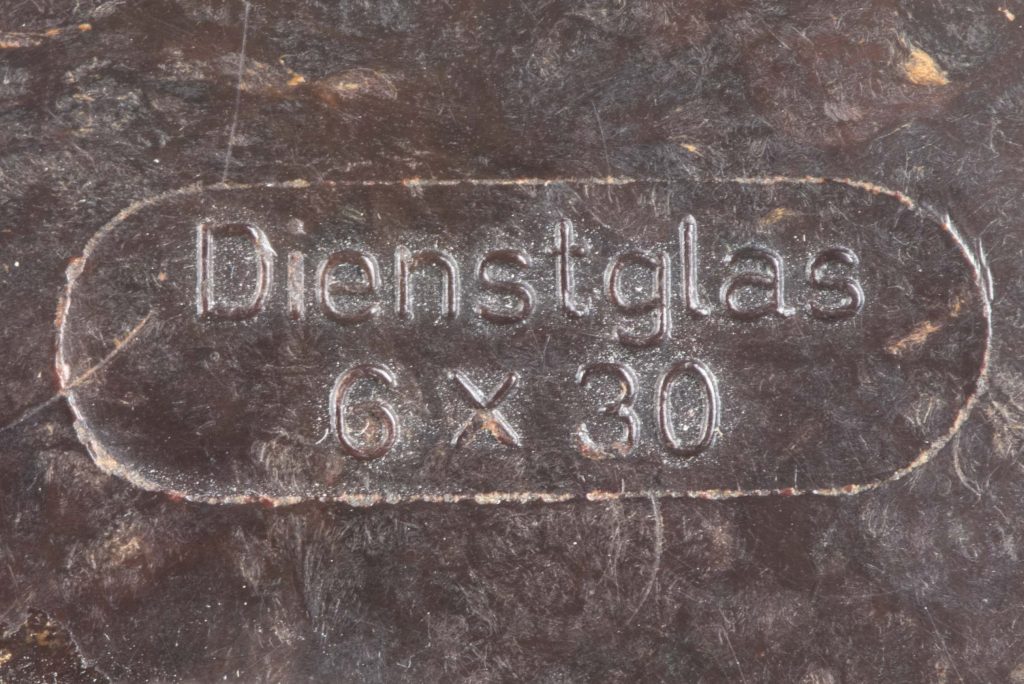

The top of the binocular housing is marked CXN on the left part and Dienstglas 6 x 30 on the right

To understand who manufactured these binoculars one can observe the large three letter code CXN on the top indicating production by Emil Busch, Rathenow. But truth be told Emil Busch just made the glass parts and metal fittings. Being a large pre war optical manufacturer it had a lot of experience and specialised in the production of lenses. But with most if not all large factories; not all parts were manufatured in house. When one were to open one of these binoculars you would observe other bakelite markings such as the mpd code 43 / Z1 indicating production by Dynamit AG, Vormals Alfred Nobel und Co, Abt. Zelluloidfabrik, Werk Troisdorf. Additionally one can observe the three letter code boa indicating Troisdorfer Kunstoffe Venditor – which was the sales representative or distribution arm for Dynamit A.G.

Bakelite markings inside the binoculars indicate the two other suppliers

The marking Z1 indicates the raw material utilised in its production being Phenolharz (Bakelit) mit Zellstoff als Füllstoff or Phenolic which is a specific type in a large array of resins collectors refer to as Bakelite. Zellstoff or cellulose fiber is a base for manufacturing paper and was produced by the fine shredding of trees. This natural filling material aided in the strength of bakelite much as the concrete reinforcement utilising metal bars.

To illustrate the array of colours one can find on these binoculars from extremely mottled to a near perfect solid deep brown colour on the right.

Dynamit and Venditor were not the only ones responsible for the production as the lenses and metal fittings were manufactured and the binocular assembly was done by Emil Busch, Rathenow. I have only seen three or four of these binoculars opened and I have only seen the markings mentioned above making me believe that there is most probably(!) no other manufacturer for the resin parts. It is known that Emil Busch often coöperated with other manufacturers for bakelite parts in their products. Some examples encountered on compasses who were produced with or for Emil Busch are MPD 45 (Presswerk-AG, Essen) and N7 (Cuno Heinzelmann-Hassberg, Berlin). It is not known if these parties also partook in the production of these binoculars.

The binocular housing is made out of three main parts.

The top part which holds a threaded barrel manufactured in zinc to affix the ocular lens. The left and right part have the markings CXN and 6×30 Dienstglas embossed in the design. The left and right top part both have corresponding parts holding the metal hinge in the middle of the binoculars. There is a loop in the material for the attachment of a leather strap. The prism is set on bakelite support points, fixed with a blued metal band with small screws on the sides. The ocular lenses have bakelite covers but have zinc tubes which thread into the binocular housing for the adjustment of focus ranging from -5 to +5. These ocular lenses are meant to be impossible to remove from the threaded tubes by means of a small notch but is as far as I can tell damaged most of the times. The right threaded optical for the ocular lens reaches right onto the prism and has a graticule attached by a ring at the end its length. Many of these binoculars have their graticule missing or sometimes loose inside the body which can be heard when moving the piece. As the ocular lenses are often removable due to damage, the graticule will easily fall out and get lost. The ocular lenses are fixed to the threaded tube with a few screws on the side. The top rings of the ocular lenses come in two different heights, most probably the short one is the first pattern. The top part is fixed to the main body with three screws. There is a loop in the material for the attachment of a leather strap.

The centre part of the binocular barrel or housing is a mere meeting point of the top and bottom parts. It features 3 screw openings or bosses underneath. Additionally it features two bosses for metal pins which were another reinforcement on joining the lower part. On the top it also features three screw bosses but I have not observed metal pins. Externally the otherwise smooth housing features a ribbed portion with 16 notches on the front for grip.

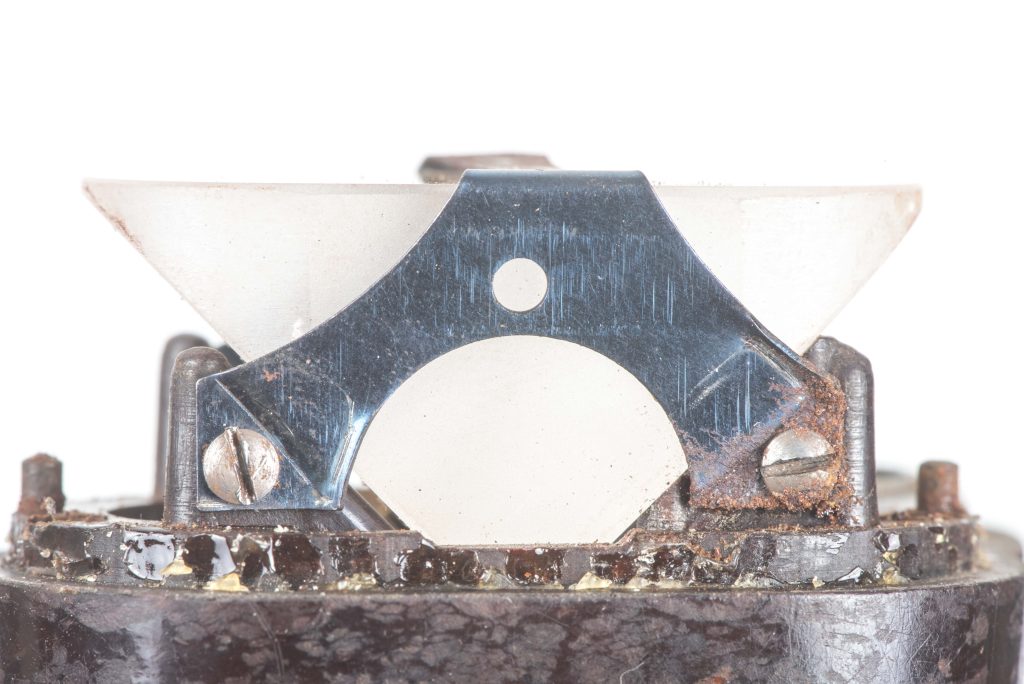

The prisms are fixed with a blued metal band with 3 screws. These prisms are unique to these binoculars as the size of the binocular housing does not correlate with anyother binocular type. Clearly visible are the two metal pins or studs that guide both the top and lower part into the correct position on the middle part and the three empty screw holes.

The lower part of the binocular housing features the lower prism, set on bakelite support points, fixed with a blued metal band with small screws on the sides. The objective lenses are fixed with a threaded ring to a zinc cone shielding light. A additional aluminium or metal ring is utilized as a dust cover. The left and right lower part both have corresponding parts holding the metal hinge in the middle of the binoculars. There is a loop in the material for the attachment of a leather strap. There are three screws and two metal pins securing this part to the middle part which seem to have been implemented after serial 384xxx. A interesting feature is the eccentric lens fitting which means the lens could be collimated which is the adjustment of the lens aim in correlation to the other side. This is a precise job which results in a perfect clear view without double vision.

These photographs show the achilles heel, the hinges are fragile and easily damaged or broken.

In between the left and right binocular housing are bakelite bridges conjoined in the middle with a round metal hinge assembly. This is also one of the common places where these binoculars are found damaged. The bridge is only a few millimeters thick between the hinge plates. Numerous damaged and or repaired examples are in collections today. There is a number of variants of this hinge. The hinge plates measure 25mm in diameter externally. The threaded tube inside can be seen in two sizes 6 and 8 mm. The pieces are finished like the other metal parts in these binoculars but this is the only part which shows several mixed paint finishes in one part.

Three different hinge setups. Note the one on the left has a smaller aperture. The locking notch is also visible on the ‘underside’ of each hinge. The locking nut can be seen on the top.

The hinge consists of three main parts. One top plate part with a fixed tube with thread on the end. This part has three small holes on the top of which one is threaded for a small fixing screw to keep it from undoing the thread of the main tube. The lower ring has a threaded hole in the middle fo screw on the tube. Additionally it has a notch which locks into the same bridge as the screw attatches to. The top parts of these hinge assemblies are marked. The hinge on the top bridge is marked with a blue triangle indicating the use of Kaltefett on ocular lense screw mechanism. The hinge on the lower bridge has the top half marked with the serial number. The lower hinge is mounted upside down, so the serial is visible underneath the binoculars. Both of the hinges lock and screwed into the right binocular housing. All the metal hardware is factory spray painted tan, blue or black. Not all binoculars came in matching colours as many mismatches can be observed and are typical.

A textbook example of a bakelite 6×30 Dienstglas

The binoculars have a specific black leather strap with black or tan painted retaining studs. Although I have seen normal straps with 4 stud holes occasionally; the specific strap encountered the most has 6 metal stud holes. This is because rubber Okularschütz or rain/dust cover for the ocular lenses was affixed with a metal stud directly trough the strap. Normally this part can be freely slided along the length of the strap. Additionally there are not two but four loops which the strap could be affixed to. The strap would be feeded trough the top loops and affixed to the lower. The leather Knopflasche or button affixing flap is of a normal pattern and affixed with two metal studs. The straps are mostly marked CXN but most of the times this marking is illegible.

Note the specific strap with 6 stud holes and 4 studs in total

The rain cover or Okularschutz is also specific for this type of binoculars. Because of the thick bakelite ocular lense covers it utilises a larger sized example which works together with these. Furthermore it can only be attached to its specific carrying strap. It features no sewn or riveted leather loops as the normal issue binoculars. The normal cover does not fit as it measures 10×3,5 cm. The special variant measures 11x4cm and fits perfectly on the Bakelite 6×30.

Three different types of cases for the bakelite 6×30 Bakelite Dienstglas

The markings of the case can be found on the lower part of the case. Right under the closing latch.

The case of these binoculars is specific as it does not fit in the standardized leather or bakelite carrying cases. As the 6×30 binoculars in bakelite were more bulky then their brass, aluminium or zinc counterparts; it needed a specificly designed well fitting case. With the fragility of the bakelite a special Pressstoff case was designed. Shaped roughly like the pre war leather 6×30 case, manufactured in the same way as Pressstoff 10×50 cases. These cases are marked CXN 4 with a Waffenamt 326. The cases are sturdy. The lid or top and the bottom half are affixed to eathother by two belt loops riveted on the back and a spring loaded catch on the front which was also used on gasmask canisters. These are always marked frn 4, frn 43 or frn 42 and have a black or tan Pressstoff pull tab fastened with one or two rivets. The Pressstoff used for the cases was mostly in black but with some variants with a tan top and possibly a complete tan case have been observed.

Inside the case is lined with a array of different types of Pressstoff which ranges from black pressed paper, vinyl or black felt. A additional two resting cushions are inside which are attached by two screws trough the side of the case. The internal lining is made in a variety of black vinyl, pressed cardboard or black felt. The lining in the lid is attached using 2 or 3 rivets that are visible on the top.

This is the textbook carrying strap for the bakelite Dienstglas case

The strap is attached to two D-ring on each side of the case. These D-rings are attached on a metal plate riveted to the side of the case. The typical strap is again specific for this type of binocular case and is made of webbing. This 2 cm wide strap is adjustable and measures 105 cm long on the longest position. It can be removed by two buckles on either end. The strap features woven holes in the material for the buckle prong and adjustment holes. The ends are finished with a ‘Lux’ type point. The sliding loop for the buckle is made out of leather. The loop for the lux points are also coarsely woven examples. I have found one other non-adjustable example without a sliding buckle.

Late ‘Ersatz’ type carrying strap

I have found another case with a strap sewn directly to the case. This strap is made out of the same material as used for the woven ‘Ersatz’ carrying straps and ammunition carrying frames. This 1,6 cm wide strap does not have a buckle and its length of 110cm can not be adjusted. My assumption is that this is the last pattern strap.

A textbook bakelite 6×30 Dienstglas – but without military markings!

I have studied a large number of variants to write this article. One of them really stands out for me personally. This example is serial numbered 422854 and unlike the others it is marked Sportglas 6×30. It does not feature the CXN or Dienstglas markings. The binoculars are mint and unissued. I contemplated them being made immediately postwar from wartime stocks bút that is not a plausible explanation. Considering the serial number this is by far not the last one produced, it is still 3000 numbers underneath the highest noted number of 425676. My guess is that this example was produced somewhere near the end of the production run and used as a presentation model for the civilian market which at that time was not existing or allowed. Looking at the tops of the binocular housing it does not show remnants of filing or removing of the CXN or Dienstglas markings. This pair of binoculars was produced with Sportglas markings prior to final assembly. I have not found any other examples of this Sportglas leading me to think that a sole presentation model is the only explanation. And if then so most probably for the Venditor firm because Emil Busch had many different civilian type maker markings denoting its production.

The serial number is engraved on the lower hinge plate

I have noted all serial numbers on approximately 100 surviving examples. When looking in Seegers book he notes that production numbers range from 407000 to 426000 and thus must have a production of about 19000 examples. This however is not complete. He also notes that no other types of optics can be found between these serials, this is also not true. When looking at the serials one should note that every specific type of binoculars received a certain block of serials allotted to that type of binoculars. This means that every serial for any binoculars in the German army is (as far as I know) unique. This is the same reason why they are noted inside the Soldbuch. However, back to the study. The lowest serial number I found was 364156 and the highest was 425676. Between these serials I also found blocks of serials used by other type CXN marked binoculars. Noting the serials and the individual details of the particular examples there are some interesting details. It shows that the first known example was produced with a 8mm aperture hinge which was followed the 6mm aperture and later the 8mm aperture was used for the remaining production. Another implementation was the reinforcement studs on the bottom part around serial 384000. The problem is that it is impossible to know whether these changes are due to improvements after field testing or they are mere production variants due to different submanufacturers in the bakelite or metal parts. My guess is there must have been about 2-5000 extra examples manufactured judging by the serials; so in total up to 23000 serials are meant to be bakelite binoculars. How many actually were produced is not certain. It is also possible that less then the estimated amount of 19000 were produced. How many have survived? I know some collectors who own up to 12 examples. But those are not the average equipment collectors. I know I have 2 examples in my collection, I know I have owned 18 examples in total and can vividly remember buying my first example.

A clear image of the bakelite binoculars in use. Complete with the typical Okularschütz

Below is the short version of the serials that are closest to observed visual changes;

364156 CXN Bakelite 6×30 is the lowest known example. It features a large aperture hinge and no visible reinforcement studs underneath. Considering the nearest serial I could find is a 15000 difference; my guess is this example is one of the earliest and most probable prototype for field testing.

365879 CXN 10×50 by Emil Busch – a larger type of metal binoculars in the same range, in between the first prototypes and the later production runs. Noted to indicate 360xxx-325xxx is NOT solely bakelite binoculars.

382190 to 384013 CXN Bakelite 6×30 feature a small aperture hinge and no visible reinforcement studs underneath

384013 CXN Bakelite 6×30 features a small aperture hinge but already has the visible reinforcement studs underneath

384478 CXN Bakelite 6×30 to 385515 feature a large aperture hinge and visible reinforcement studs underneath

396849 to 400640 CXN ‘stumpy’ 10×50 binoculars by Emil Busch – a larger type of metal binoculars in the same range, in between the first prototypes and the later production runs. Noted to indicate 360xxx-325xxx is NOT solely bakelite binoculars.

405979 to 425676 CXN Bakelite 6×30 features large aperture hinge and visible reinforcement studs underneath – the last run of bakelite binoculars.

426503 CXN tan Uboot 8×60 lowest number – no more bakelite binoculars

Another explanation in the gaps of production can be sought in the research of the factories involved with the production itself.

Dynamit AG at Troisdorf knew it would be a target for the Allied bombing campaigns as its main product was explosives. The factory constructed a complete dummy facility, complete with camouflage netting, on the outskirts of the town to divert Allied bombers. Even then it was bombed with regular and firebombs on 16.6.41. In 1943 it was hit numerous times by allied bombers. On 29.12.44 the Celluloid part of their factory was totally destroyed and the other factories partially damaged. The last heavy bombing on 8.3.45 halted all production due to damage. On 13.4.45 the Americans marched into the town and its industry. Dynamit AG had up to 1300 Jewish forced labourers in 1944 and 1945.

The Busch factory in Rathenow was located west of berlin. This location meant that it was not thát interesting for allied bombing campaigns as most of them were targeted towards Berlin. But being right in the line of flight path to Berlin it meant that any American or British bombers dumped their unused bombs on the way back, often hitting Rathenow. The worst raid was on 18.4.44 when American bombers could not reach Berlin due to heavy Flak and released their payload on Rathenow instead. Rathenow was facing the Red army between april 25 and the 6th of may 1945. Rathenow and the Busch factory was destroyed up to 90%. Emil Busch AG operated 6 of its own concentration camps of the 33 camps located in Rathenow with at least 1600 forced laborers. All 6 of those camps were fully assigned to the company’s facilities. After the liberation the Russians dismantled the factory and moved it to Russia.

It is likely that the observed gaps and irregularities in the serial range correspond directly with wartime disruptions at both subcontractors. Dynamit ag in Troisdorf, responsible for the bakelite bodies, suffered repeated bombings in 1943, with the Celluloid and resin facilities completely destroyed on 29.12.44 and all production ceasing after the heavy raid of 8.3.45. At the same time Emil Busch in Rathenow was hit by its worst air raid on 18.4.44, causing major damage and a temporary halt in assembly. These overlapping events make it plausible that production dropped significantly between mid 1943 and late 1944, with a final collapse in the first months of 1945. The serial gaps and changes in hinge types, colours and reinforcement studs fit well within these periods of disrupted supply and reduced output.

Who received these bionoculars? A well known photographs taken during the Ardennes offensive shows several SS men from the SS-Panzer-Division Leibstandarte-SS Adolf Hitler wearing these binoculars. This appears to be the earliest confirmed photograph which can be tied to a time and place of these binoculars, and the available evidence suggests that they were one of the final models designed, field-tested, and issued to the Wehrmacht and Waffen-SS. Although some physical examples supposedly were found in Normandy this is for me the earliest proven issue. Several other images exist including one Scharfschütze, one NCO armed with a MP44 posted above and one of officers in may 1945 near Berlin. Contrary to popular belief and their fragile nature; they are actually excellent binoculars. Wether they were produced to save on raw materials or to innovate technically; they succeeded either way. With this new type of binoculars they paved the way for future military optics.

The left shows the bakelite 6×30 binoculars

Serials for the Bakelite 6×30 Dienstglas

364156 Large aperture tan hinge, blue rings, tan ocular tubes with reinforcement studs

382190 Small aperture tan hinge, blue rings, blue ocular tubes without reinforcement studs

382735 Small aperture tan hinge, blue rings, blue ocular tubes without reinforcement studs

382909 Small aperture tan hinge, blue rings, blue ocular tubes without reinforcement studs

382747 Small aperture tan/blue hinge, blue rings, blue ocular tubes without reinforcement studs

– implementation of reinforcement studs

384013 Small aperture tan/blue hinge, blue rings, tan ocular tubes with reinforcement studs

– implementation of large aperture hinge

384478 Large aperture tan hinge, blue rings, tan ocular tubes with reinforcement studs

384715 Large aperture tan hinge, blue rings, blue ocular tubes with reinforcement studs

385505 Large aperture tan hinge, blue rings, blue ocular tubes with reinforcement studs

385515 Large aperture tan hinge, blue rings, tan ocular tubes with reinforcement studs

– block of CXN ‘Stumpy’ binoculars

405979 Large aperture tan hinge, tan rings, blue ocular tubes with reinforcement studs

406421 Large aperture tan hinge, tan rings, blue ocular tubes with reinforcement studs

406888 Large aperture tan hinge, blue rings, tan ocular tubes with reinforcement studs

407167 Large aperture tan hinge, tan rings, blue ocular tubes with reinforcement studs

410210 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs – moulded grade scale at left top hinge

410408 Large aperture tan / blue hinge, blue rings, tan ocular tubes with reinforcement studs

410689 Large aperture tan / blue hinge, tan rings, tan ocular tubes with reinforcement studs

410767 Large aperture tan / blue hinge, grey rings, tan ocular tubes with reinforcement studs

411146 Large aperture tan / blue hinge, tan rings, tan ocular tubes with reinforcement studs

413138 Large aperture tan / blue hinge, tan rings, tan ocular tubes with reinforcement studs

413245 Large aperture tan / blue hinge, tan rings, tan ocular tubes with reinforcement studs

413520 Large aperture tan / blue hinge, tan rings, tan ocular tubes with reinforcement studs – repaired reinforced metal tube between both hinges.

416158 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

414698 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

415405 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

416931 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

417326 Large aperture tan hinge, missing rings, tan ocular tubes with reinforcement studs

418691 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

421053 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

422854 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs – marked Sportglas

423195 Large aperture tan hinge, tan rings, grey ocular tubes with reinforcement studs

423506 Large aperture tan hinge, tan rings, grey ocular tubes with reinforcement studs

424045 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

424718 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

424816 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

425391 Large aperture tan hinge, tan rings, tan ocular tubes with reinforcement studs

425394 Large aperture tan hinge, black rings, tan ocular tubes with reinforcement studs

425676 Large aperture tan hinge, black rings, tan ocular tubes with reinforcement studs

Sources;

Militärische Ferngläser und Fernrohre, Hans Seeger, Hamburg, ISBN 3-00-000457-2

Serials:

Wehrmacht-Awards Forums

War Relics forums

A special thanks to Andy and Olaf!