MG34 and MG42 ammunition boxes

A brief history on the design and paint finish variants for the MG34 and MG42.

Table of contents;

1 Ammunition case designs;

– Patronenkasten 34 in Aluminum

– Patronenkasten 34 in Steel

– Patronenkasten 41 in Steel

– Czech ZB37 ammunition cases

2 Paint finishes

– Factory paint finishes

– Non factory paint finishes

– Other uses and tactical markings

With the introduction of the belt fed machinegun during the first world war a new doctrine for carrying ammunition was developed. Unlike the large wooden crates that have thus far served as a way to delivering ammunition to the front line and to be distributed amongst the troops; a need arose for a ammunition case that could be used in the direct vicinity of the machine gun and even during the operation and movement of the piece. A elongated flat wooden case that fitted 250 or 300 rounds was developed. This was followed by a metal cased design which was produced roughly in the same form until 1941.

The Germans were the first to fully implement a general-purpose machine gun or Einheitsmaschinengewehr. This machine gun was meant to be in the centre of every infantry group or Gruppe bringing more firepower to the front.

Whilst other armies still struggled with multiple machine guns for multiple roles the German army was (as so much of the times) way ahead. With the implementation of Blitzkrieg tactics the Germans needed a machine gun that was light, accurate, reliable and had a high rate of fire. The MG34 was a excellent air-cooled, recoil operated light machine gun that could fire semi- and automatic at 850 rounds per minute. It could be easily adapted to fulfill different roles on the battlefield. As a light machine gun it was light enough to carry around and fast enough to lay down suppressive fire. On a tripod with the addition of a sight it was a anti-aircraft weapon and on the MG34 Lafette a excellent sustained-fire machine gun. The Germans were the first to fully implement the tactic that every infantry squad or Gruppe worked around a light machine gun. During the war when materials became more scarce and production had to be sped up the Germans developed the MG42. This new machine gun had a even more devastating rate of fire of 1200 rounds per minute. It was efficiently made of stamped steel and had a different bolt.

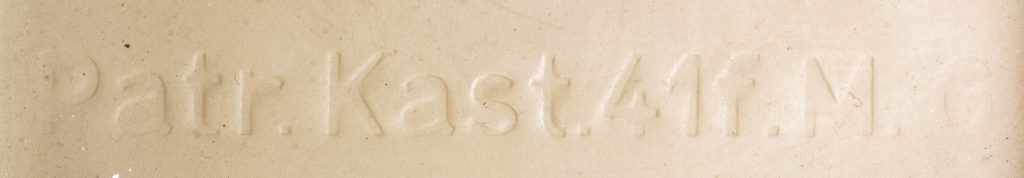

The Patronenkasten 34 was developed to be a lightweight ammunition box to carry ammunition for the MG34. It was capable to carry 300 belted 7,92 mm rounds. The first models were manufactured in aluminium and was also produced in steel starting in 1938. The Patronenkasten 34 was well designed but had a complex design with a slanted lid and a clasp closure which often broke. In 1941 the Patronenkasten 41 in steel was introduced. This steel ammunition box had a straight lid and a clasp closure on the side. Also it featured a rubber seal in the lid making it waterproof. On the short sides they were marked Patr. Kast. 41 f. M.G. which is short for Patronenkasten 41 für Maschinengewehr. The manufacturers marked the cases in the lid in the recessed area for the carrying handle. These cases were marked with maker logos until 1941 when it was replaced with a three digit maker code system.

Patronenkasten 34 in Aluminum

The first MG34‘s were most probably issued with first world war issue Patronenkasten 15 ammunition cases in steel. These would be replaced by the Patronenkasten 34 which in general is the same design but made in aluminum which proved strong and lightweight but not durable in a multiple year conflict. The aluminum cases are often referred to as being lightweight Fallschirmjäger issue pieces but this is incorrect. The truth is that these cases were produced for the whole Wehrmacht between 1935 and 1940 when its production was completely replaced with steel examples.

The cases have a ingenious design where the handles are placed off centre making it more comfortable to carrying not one but two cases at the same time as illustrated below. The handles are all placed in neatly recessed parts of the box creating a completely flat surface when the handles are fully retracted which simplified stacking. The handles have leather and later Pressstoff grips for comfort on the hands whilst carrying. The two handles on both narrow sides of the box also have these reinforcements. The centre of the main carrying handle has a dent which creates a place where a clasp hook of a Tragegurt 34 can grip or it can be supported on the Lafette.

The weak point on both the aluminum and steel Patronenkasten 34 was the closing latch which is often damaged, missing or simply not closing firmly. The fault is in the design, the emplacement of the latch itself and the materials chosen. The stamped steel closing latch is prone to damaging whilst I have never seen a broken cast steel closing latch.

Whilst early closing latches are made out of cast steel; the later variants were stamped in steel. Cast and stamped closing latches were used in the production of the aluminum ánd steel cases being produced side by side eventually. I have found that most of the early production cases were made with cast steel latches indicating this probably was the first model. The handles, hinges and closing latches were all affixed to the main body by means of riveting.

Patronenkasten 34 in Steel

The first steel cases were produced in 1938 and stayed in production until 1942. The steel Patronenkasten 34 was a improvement on the aluminum examples but it did put more weight on the troops. In general there are 2 variants which are both produced with both cast and stamped steel closing latches. The two variants can be recognized by the welding of the main body of the case. One variant is welded at the corners like the aluminum Patronenkasten 34; another is made with spot welded folded over corners.

Patronenkasten 41 in Steel

In 1942 the Patronenkasten 34 replaced with the Patronenkasten 41 which was a improvement on the durability; the design was stiffer and was made of square folded steel into a boxed shape design with its corners creating a recess and overlapping the closing latches. Whereas we only find the name for the Patronenkasten 34 in the period manuals; the Germans conveniently marked the model 41 case with Patr. Kast. 41 f. M.G. indicating Patronen Kasten 41 fuhr Maschinen Gewehr.

A uncommon variant Patronenkasten 41 has dimples in the side, these are placed right behind the narrow sides of the case. These are probably welding guides for the side panels. The black painted band is probably yet another ammunition specific marking. `The dents or dimples can be seen inside and out of the case.

The Patronenkasten 41 featured two closing latches on both far sides, one to open it and another to merely loosen the lid. These latches were attached with a swivel hinge on both sides. This hinge has a secondary swivel point which reduces the stress to the hinge and its closing latch. The handles, closing latches and hinges were both riveted or spot welded to the main body of the case. There are two different styles of closing latches; one is actually a Patronenkasten 34 example which was later replaced with a similar example but with a stamped cross shape for reinforcing purposes. Having observed many Patronenkasten 34 and – 41 I can testify the 34 model is much more prone to having damaged latches. I have never seen a Patronenkasten 41 with a damaged latch whilst I’ve seen many Patronenkasten 34 damaged or unable to close.

The Patronenkasten 41 featured a new steel lid which featured a rubber seal creating a water and dust proof seal. This was a major improvement on the earlier pattern. The lid featured a large pressed shape around the handles to create extra sturdiness which was later omitted simplifying construction. This is mostly seen on 1945 examples yet several 1944 dated examples can be observed with this feature. The early cases had a rivet punched in the lid near the main carrying handle. The exact purpose for this is unknown, if someone would, please reach out to me – I’d love to learn!

Czech ZB37 ammunition cases

As the Germans occupied Czechoslovakia they took over most of their military stocks including weapons and equipment. This box for the Czech ZB 37 machine gun or MG 37 (t) originally had a slope riveted inside to stack the ZB ammunition belts properly. This slope was removed by the Germans and the leftover holes filled in with aluminum rivets prior to a tan repaint. The case has the same slanted lid design as the Patronenkasten 34 but has the closing latch on the side in stead of on top. These cases can be found in use throughout the Wehrmacht for the MG08-15, MG34 and MG42. I have encountered most of them in tan paint with one or two camouflaged and one in Red Cross configuration.

Factory paint finishes

The paint finish on the aluminum Patronenkasten 34 came in different tones but most of them were primed in red oxide paint prior to its final coat. There are many different factory camouflaged or field repainted ammunition cases to be observed. Most of these factory finishes or field repaints followed the German army regulations for vehicles, ordnance and equipment.

Reichswehr camouflage factory paint pattern

During the Reichswehr era, the Germans adopted a three-tone camouflage pattern that was based on the Mimikri camouflage pattern from the first world war. The paint scheme was made with Erdgelb-matt or matt earth yellow, Braun-matt or matt brown, Grün-matt or matt green. These cases were produced between 1935 and 1939. The camouflage paint, unlike most other repaints discussed in this section was factory applied to the cases. This camouflage pattern can be observed on both aluminum and steel cases.

On the 12th of July 1937 all troops were ordered to overpaint their equipment and vehicles in Dunkelgrau or dark grey paint combined with Dunkelbraun or dark brown. This was done with either hand or spray applied paint on top of the three-tone camouflage finish. Even when three-tone Reichswehr pattern camouflage cases were still coming straight from production. We can observe many of these early cases being overpainted wartime or even pre war. It is not uncommon to see these three-tone Reichswehr camouflage finishes on TOP of a three-tone Reichswehr camouflage finish.

Factory Brown factory paint camouflage

The second factory paint finish variation was introduced in 1937 and was factory applied. The camouflage pattern consists of Dunkelgrau or dark grey paint combined with Dunkelbraun or dark brown. This is a very subtle camouflage pattern which can be seen on the cases but is hardly noticeable due to a nonexistent difference in contrast.

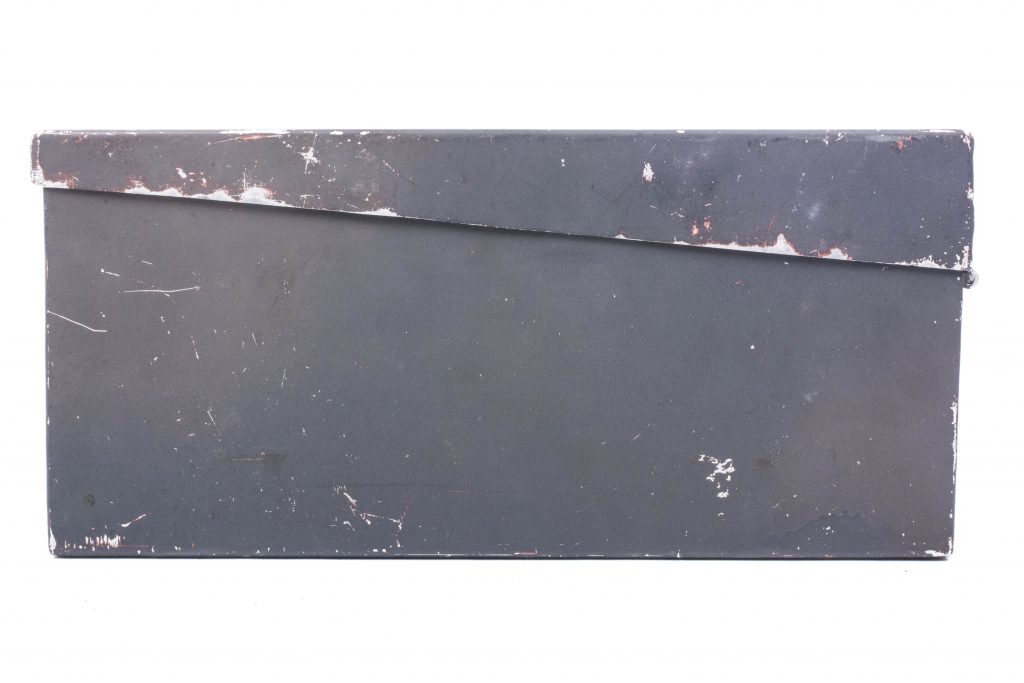

Factory dark grey factory paint finish

In July 1940 the brown paint was suspended on the factory paint finish to save paint in a war effort. This resulted in the Patronenkasten 34 remaining being produced in Dunkelgrau until 1942. This paint finish was also used on the Patronenkasten 41 for a short period in 1942 until it was replaced with Dunkelgelb.

Factory tan paint finish

Shortly after the introduction of the Patronenkasten 41 in 1943 the Dunkelgelb or dark yellow paint was introduced as a standard colour for vehicles, ordnance and equipment. This colour is also known as ‘Ordnance Tan’ or Sandgelb. The inside of the boxes were also finished as the exterior yet oxide red or unpainted interiors also exist.

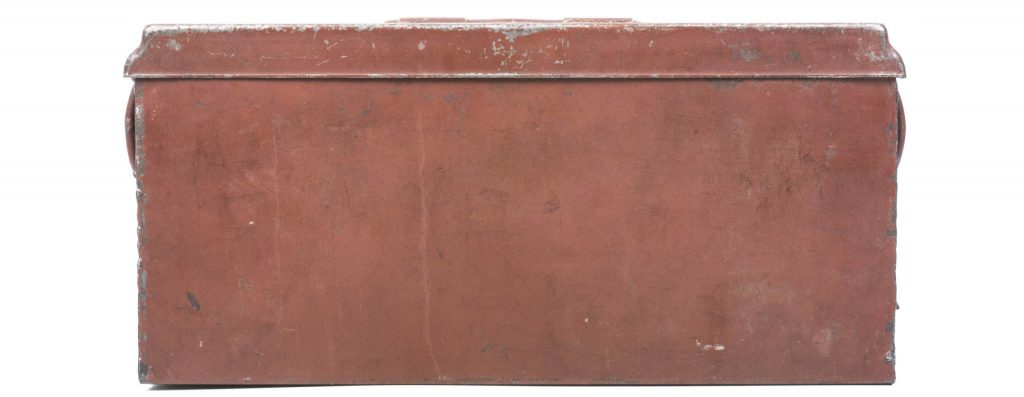

Red Oxide factory paint

At some point several batches of Patronenkasten were factory finished in red oxide paint as normally used as a primer or camouflage colour. It’s unclear wether these cases were meant to be issued like this or factory defects. I have also seen Patronenkasten 41 in green camouflage paint as used with the three-tone camouflage finish. This could also suggest as with some late war camouflage schemes used on halftracks or vehicles such as the Hetzer whereas the wheels would painted in single yet differentiating colour. It could be that these cases were meant to be used in combination with tan and green examples; but this is speculating.

Dark blue factory paint

At some point I’ve found a batch of 100 Werkzeugkasten dated 1945. The interesting feature to these cases is the fact they are all dated 1945, stenciled and spray painted Werkzeuge to the side. They are all finished in dark blue or Graublau paint suggesting this was the last factory colour used by the German army. As you can see by the large number of running paint drops its visible they must have been rushed into production. The dark blue or Blaugrau was meant to surpass the tan paint that was the standard colour used up till then. This same paint was also standardized for belt buckles, uniform buttons and helmets regardless of branch.

Non-factory applied camouflage paint finishes

Tarne Dich und dein fahrzeug – auch für kurze zeit,

Tarnung spart dein blut, und das deiner kameraden!

Camouflage yourself and your vehicle, even for short periods! Camouflage saves your blood, and that of your camerades! – was a motto printed on a German army poster. This phrase emphasized the German army tactic of adopting camouflage. The Germans had one the most advanced armies during World War Two and applied this to most uniforms, vehicles and equipment.

Certain field equipment and ordnance followed the specified orders to apply camouflage paint just as motorized units camouflaged their vehicles. This was occasionally also applied to smaller equipment such as helmets, gasmask canisters and MG ammunition cases. These orders to camouflage tend to be carried out most by troops which were either widely motorized or stationed. Motorized troops had to camouflage their vehicles. These vehicles would mostly be painted in the motor pool by the troops manning the vehicles. Another type of unit you’ll see with a lot of camouflaged items are stationary troops preparing for invasion. There are many examples of units serving on or near the Atlantikwal having extensive camouflaged equipment setups. Unit applied camouflage paint is mostly consecutive and a defining pattern or ‘finger print’ per unit can be seen.

Most of these paint finishes were applied with a spray gun but hand applied finishes can be observed. These spray guns would be hooked up to the air compressors that came on maintenance trucks and half-tracks. When camouflaging the vehicles of a unit they would often also take into account camouflaging other equipment. Time permitting that is.

Tropical ‘Tan’ camouflage paint

As soon as the Germans started fighting in North Africa and Crete, they started implementing tan paint as a desert camouflage on their equipment. There are various shades of tan paint but these are the most common. I have chosen to only include pre 1941 dated examples as to make sure they were made prior or during the Afrikakorps period. A large number of equipment and helmets were also camouflaged for the invasion of Crete later in 1941.

Winter Whitewash camouflage paint

When the Germans encountered harsh winter conditions the implementation of winter camouflage paint was ordered. This paint would often be chalk, thinned with water and applied on smooth metal surfaces. The reason for chalk being used for this purpose is the reversability of this camouflage finish when in the spring the white camouflage paint would just wash off with water. Hence the term ‘white wash’. The Germans also used paint next to chalk on items which would see more hard use such as ammunition boxes. These camouflage paint finishes first adopted in 1941.

Bild 183-2005-0519-500

Westfront, 18.1.45

Fallschirmjäger an der Ardennenfront.

Bei den harten Kämpfen im Frontbogen im Westen sind auch Fallschirmjäger eingesetzt. In den Ardennen liegt Schnee, und alles wird weiss. Auch Stahlhelme, Ferngläser und Waffen. Bundesarchiv

Grey or sea green camouflage paint finish

This paint finish is often referred to being Kriegsmarine or Küsteanartillerie (coastal artillery). These units were stationed along the coast and or at salt rich environments. These troops had a lot of time on their hands and therefor did many maintenance and preparation work. Many of these units used their time to upgrade their equipment, but not all. Upgrading also included painstakingly painting every bit of equipment in a grey paint, including these ammunition boxes. Kriegsmarine and or Küstenartillerie personnel also were known to adopt the three-tone camouflage pattern later on.

Two or Three tone ‘Normandy’ camouflage paint finish

Another typical, tell tale camouflage pattern is widely known as the three tone or ‘Normandy’ camouflage pattern. This camouflage pattern is however not exclusive to the Normandy area and was adopted a year earlier. In February 1943 the German army issued an order to paint all vehicles in tan colour, oversprayed with green and brown shapes. It was to be hand applied or spray painted. Many variants in shapes and application exist. This two or three tone camouflage pattern was adopted at a broad range for all troops from 1943 onwards. It is not specific to Normandy, but I promise I will write another article on that matter soon! Back to the subject; here are 9 different two or three-tone camouflage pattern ammunition cases for comparison.

Other uses and tactical markings

There are many period painted markings to be observed on these cases indicating its contents, unit or individual weapon serial. These markings are mostly hand painted but sometimes also stencilled or penciled. These markings were all unit applied. There are probably way more variants still to be found!

E-Kasten for the Ersatzteilkasten

The Ersatzteilkasten was the small supplement case which contained spare parts, oilers, bolts and tools.

V-Kasten for the Vorratskasten

The Vorratskasten was small storage box which mainly contained small technical parts of the MG bolts.

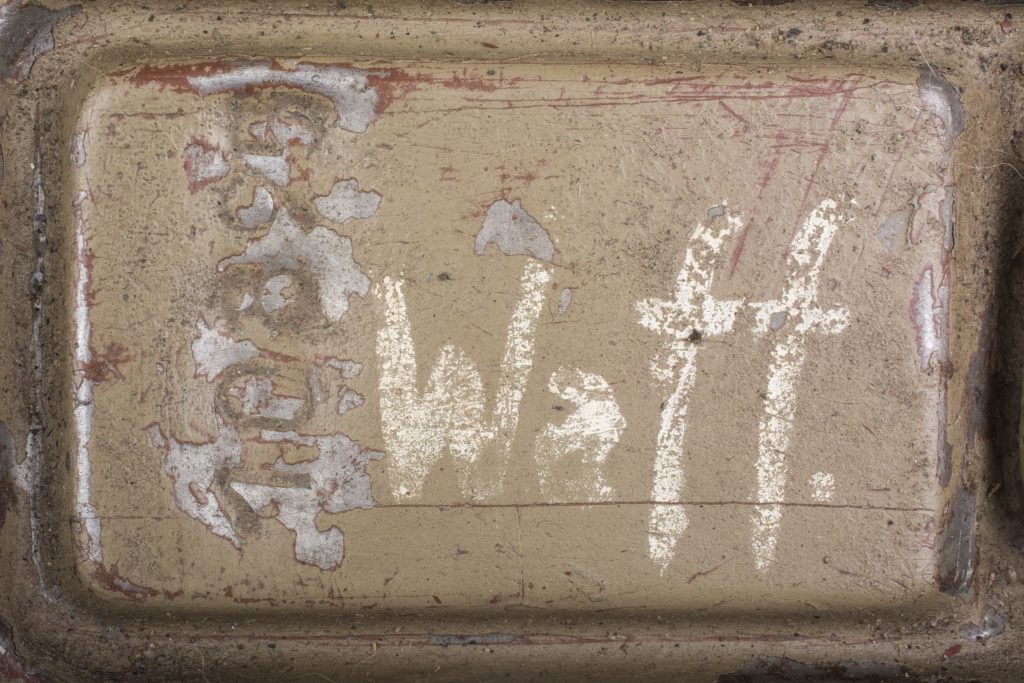

W-Kasten for the Werkzeugkasten;

The armourer or Waffenmeister had a foldable tool kit that fit exactly inside The Patronenkasten 34 and Patronenkasten 41. The Werkzeugkasten was a collapsible tool boards contained the basic tools to service, repair and replace parts on the MG34 and MG42. These first came in standard Patronenkasten 34 which would be marked as such by the Waffenmeister.

P-kasten for the Petroleumkasten

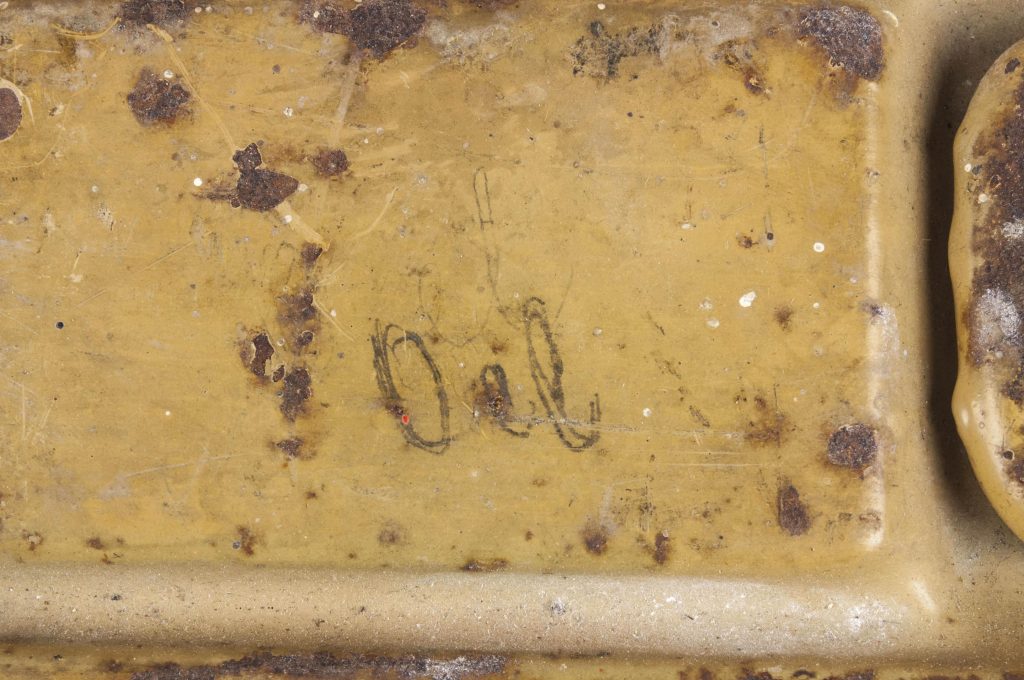

The Petroleumkasten carried two large oilers containing Oil and Petroleum. These two cleaning and lubricating liquids were vital in the maintenance of the MG34 and MG42. These cases were marked with various letters and text but the most common are marked P, O or Oel.

G-kasten for the Gurtfuller

The ammo belt filler or Gurtfuller also had it’s own case and it’s marked with a G.

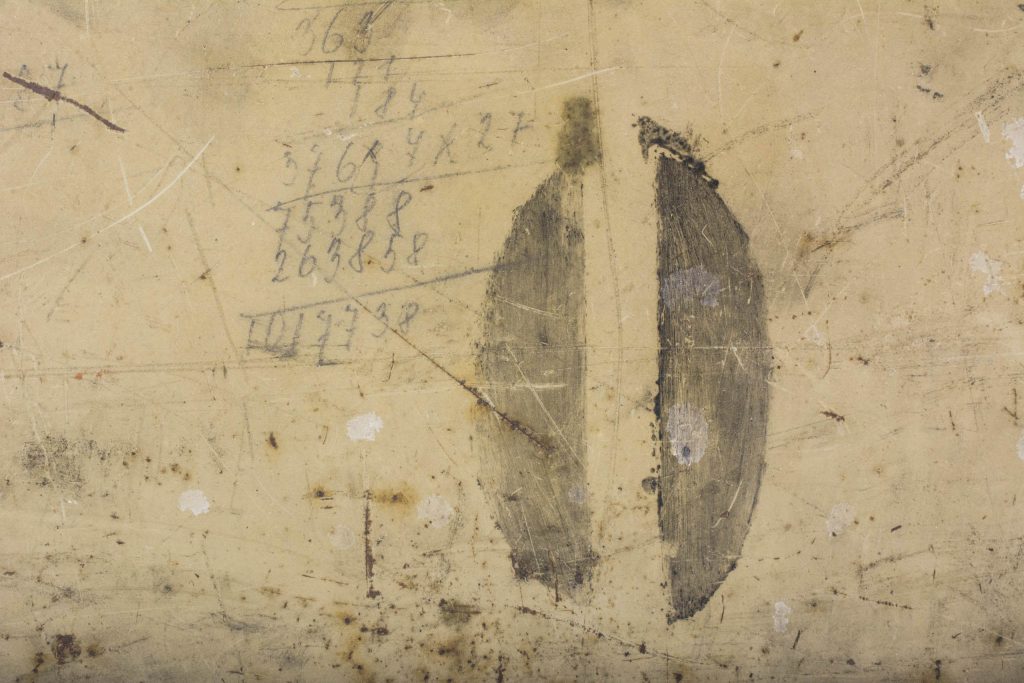

Weapon serial numbers

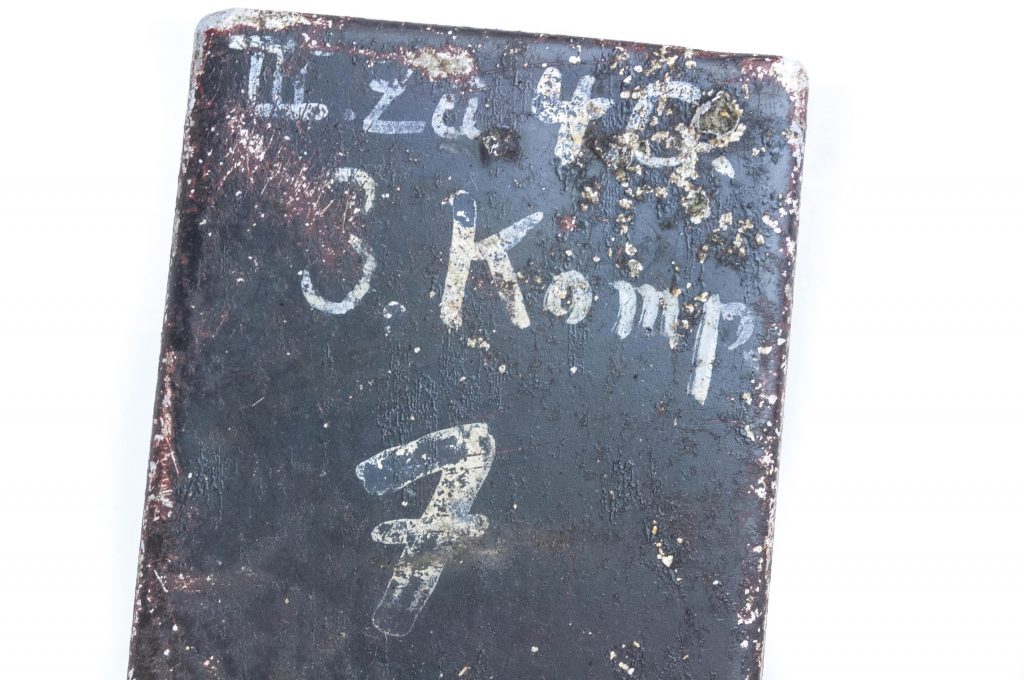

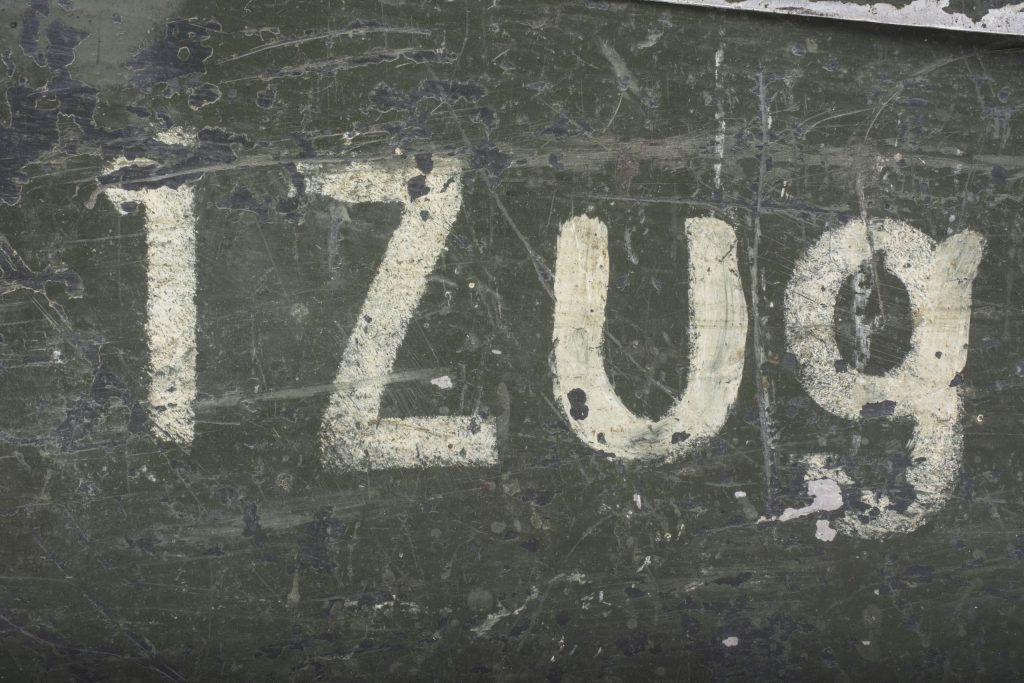

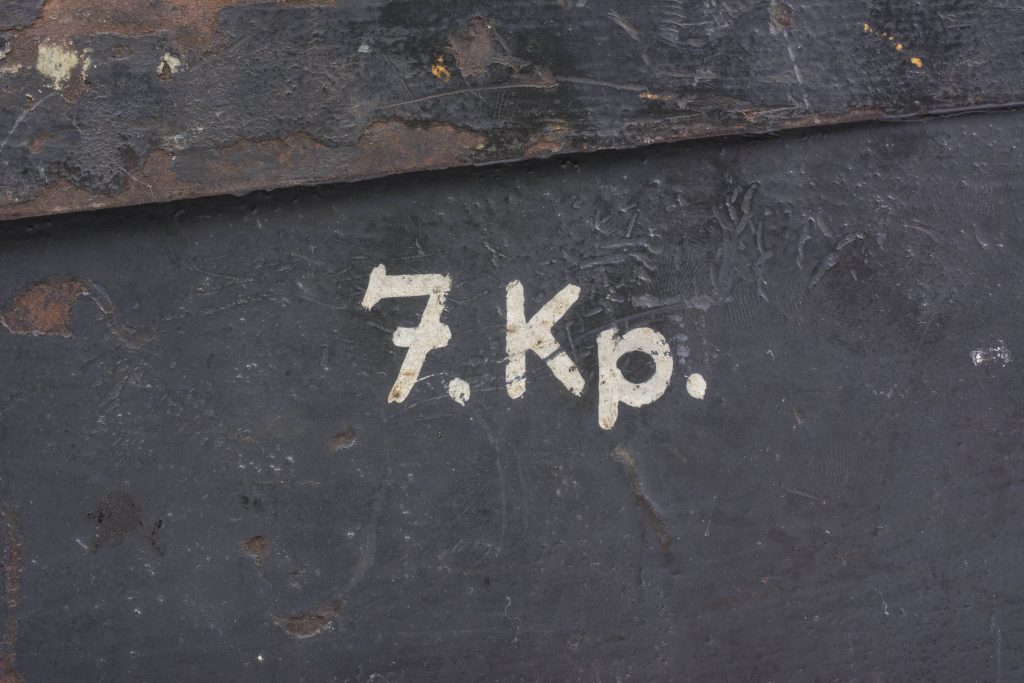

Fighting in units where every unit had many machineguns and the individual soldiers were being held accountable for all its accessories; it was very common to mark ammunition cases to individual weapon serials. German army doctrine had one (or two for Panzergrenadier units) MG in every 10 enlisted men. Each MG had at least 2-4 ammunition cases which were all in the responsibility of the MG crew. If they would lose equipment they would most probably be punished for it. Therefore these cases were often numbered with the weapon serial to keep track of which was where. The same goes for individual Kompanie and Gruppe markings which are often observed.

Unit markings

Often these ammunition boxes were marked with individual Division, Regiment, Zug, Kompanie or Gruppe. This also is a way to keeping everything individual and organizable.

Ammunition markings

Medical or Sanitäter cases

There are several wartime examples of wartime converted Patronenkasten 34 and 41 in use by Sanitäter or as first-aid kits. Even though medical orderly pouches, large Sanitäter cases and Tornisters existed; the troops in the field needed a sturdy box to transport some of their life saving equipment. Most of these cases are bone standard with the addition of a Red Cross painted on a white roundel indicating its contents. I’ve seen several other variations as well but these are the most common examples.

Sources

A great website about the different MG accessory cases is called Bergflak. This website is a great source on information on German weapons and accessories. A must see for any enthusiast!

https://www.bergflak.com/pkasten.html

https://www.bergflak.com/ezvkasten.html

Paint colours and camouflage schemes; A great writeup about all the different colours and orders for the German army vehicles and equipment. A good study for vehicle and weapon enthusiasts!

https://panzerworld.com/german-armor-camouflage

Thanks to everyone who contributed by letting me photograph their cases and collectors reaching out with information!